ASSEMBLY TECHNOLOGIES

FOR SMART Medical DEVICES

用于装配医疗部件和设备的高精度技术 医疗部件和设备

医疗行业致力于实现产品微型化,以提高人体监测和治疗系统的易用性。与此同时,越来越多的智能功能和智能电路需要集成到尽可能小的空间内。

体外诊断试剂盒就是一个很好的例子,它可以在不离开医生检查室的情况下进行快速检测;血压监测套件也可用于血样采集和输液。

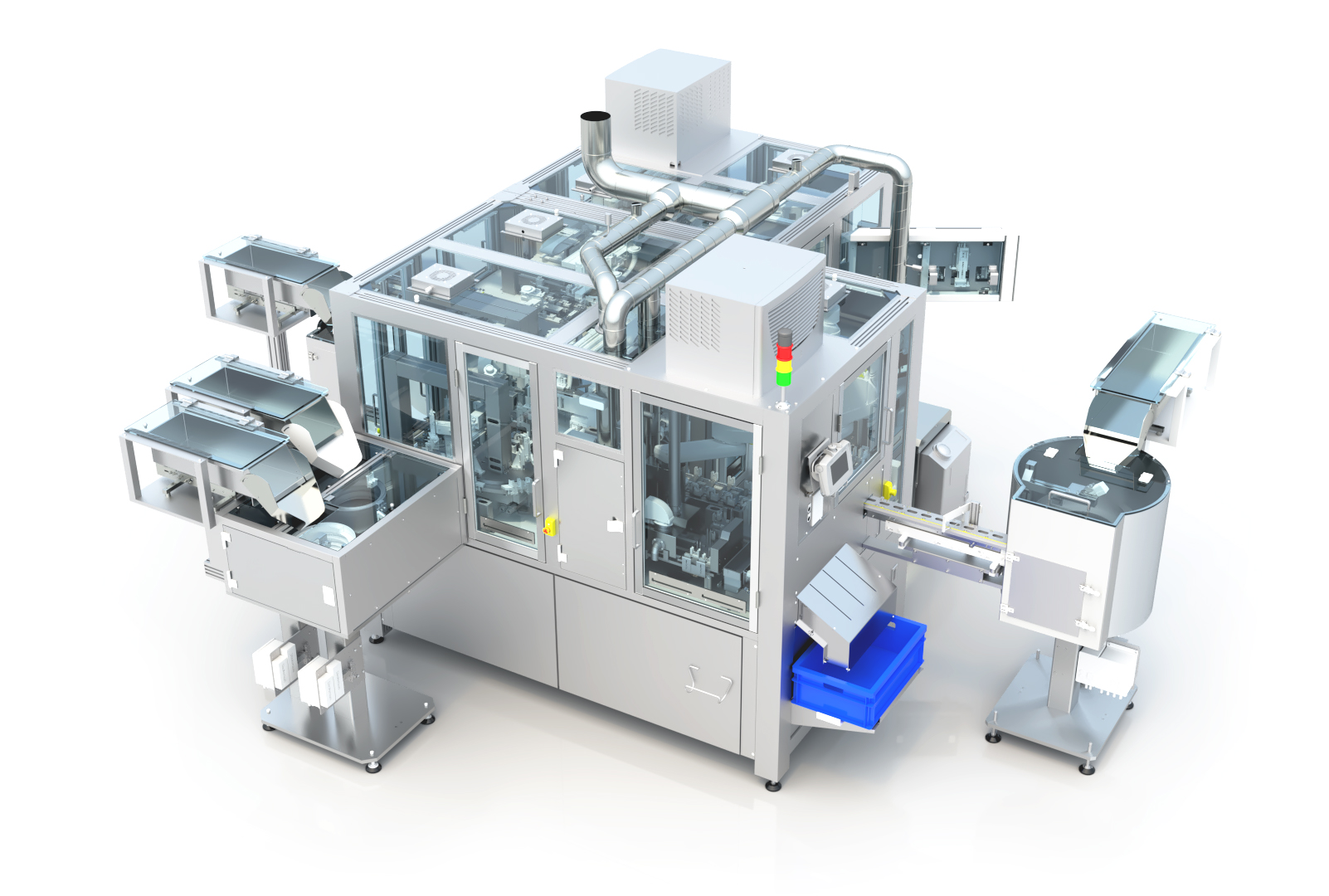

对于医疗器械制造商,XENON 可提供广泛的生产技术和个性化定制的设备方案,从用于小批量生产的半自动化设备一直到全自动装配线。

我们经验丰富的工程师团队努力工作,确保自动化设计适用于洁净室和卫生清洁,并确保生产和测试数据记录详实、可追溯。

我们的专业项目经理会在项目的每个阶段为您提供支持。公开透明的沟通使您能够有效地保障产品质量,实现项目的关键里程碑。

装配组合

药物输送装置

体外诊断装置

80 多种标准化技术 - 主要类别

上料与給料

振动上料、鼓式上料、

离心上料、柔性上料

搬运与处理

SCARA 机械手、6 轴机械手、多轴龙门系统、高速取放装置

配药

胶水、密封胶、Lacqeur、焊膏、填充化合物、化学键合溶剂、2K 材料、

真空喷涂

超声波焊接

塑料和金属部件、薄膜、无纺布材料

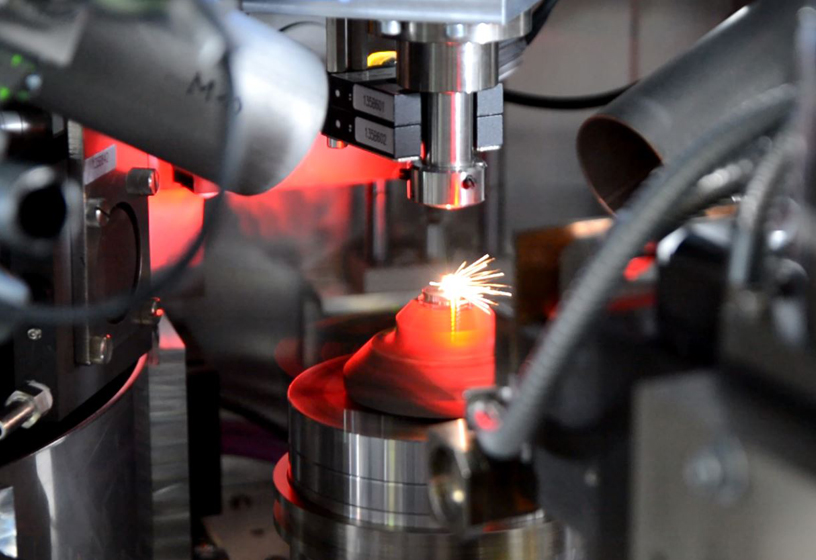

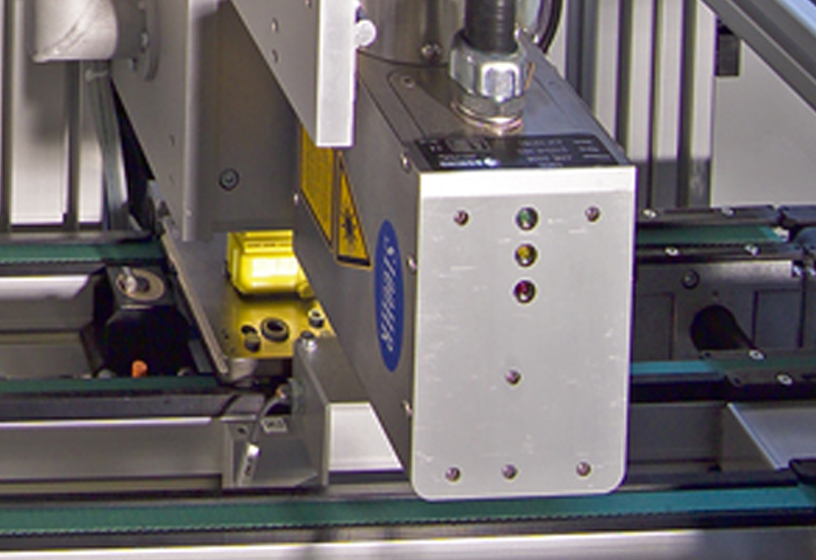

激光

切割、焊接、标记、焊接、

清洁、剥离、表面处理

测试

视觉控制(AOI)、质量控制、泄漏测试、流速测试、电气测试、

生产线末端测试、力和距离测量

标记

激光打标、喷墨打标、

标签、热转印印刷

包装

托盘包装、管式包装、SMD 胶带包装(Tape&Reel)、袋式包装、

泡罩填充和密封

高速线性传输系统

快速、紧凑、灵活 - 适用于医疗行业的载体运输系统

功能与优点

紧凑型

结构

模块化

可扩展

高精度

周期短

变速

速度曲线

部件运输

顺畅

参考产品

参考产品

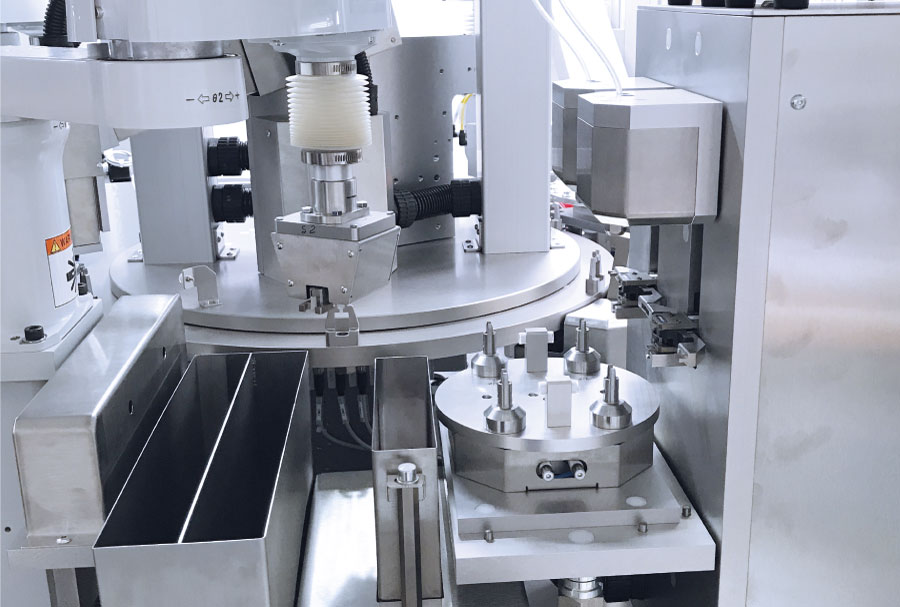

自动装配血压传感器

客户产品

用于连续生理压力测量和其他血液动力学参数的一次性冲洗组件。

自动化要求

- 最终产品的全自动装配和测试

- 高性能和高技术可用性

- 安全和经认证的质量标准

- 无尘室设计

- 复杂塑料部件(散装材料)的自动送料和装配

- AOI 焊接检测

- 化学键合

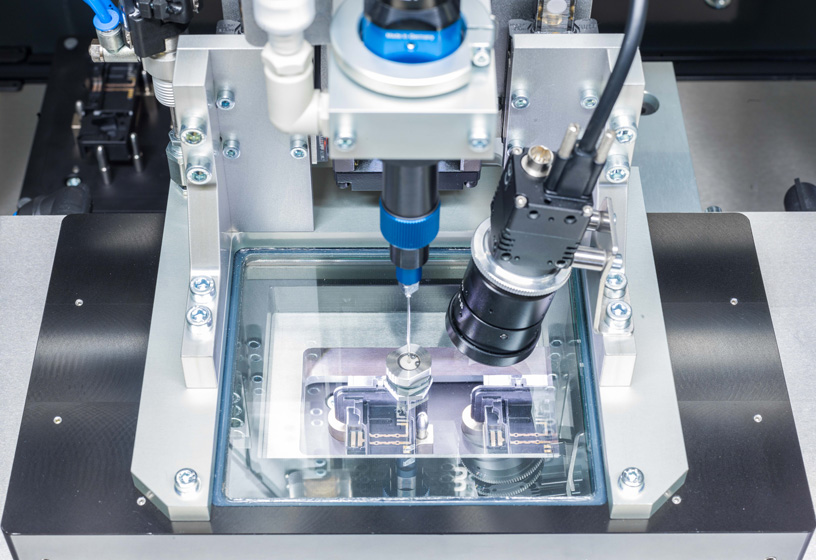

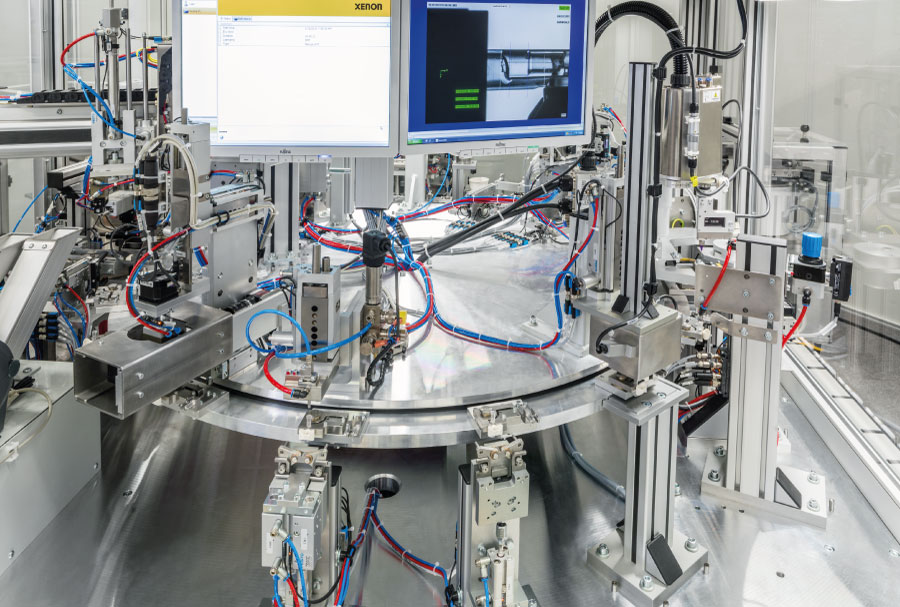

医疗连接器的自动装配和测试

客户产品

用于连续葡萄糖监测的一次性连接器

自动化要求

- 最终产品的全自动装配和测试

- 高性能和高技术可用性

- 安全和经认证的质量标准

- 无尘室设计

- 微型密封件和柔性组件的自动送料和装配

- 和柔性组件

- 泄漏测试

- 力控制装配

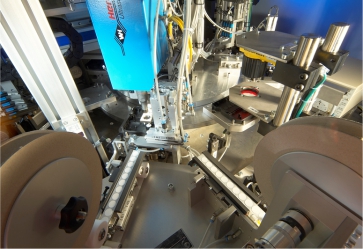

用于医用冲洗设备的装配机

客户产品

用于连续测量生理压力和其他血流动力学参数的医用冲洗设备

自动化要求

- 最终产品的全自动装配和测试

- 高性能和高技术可用性

- 无尘室设计

- 硅胶散装材料的自动进料和装配

- 柔性组件的光学检测和装配

- 高精度粘合/分配

我们医疗行业设备的常规产出:

0 -

0